SigmaView Systems - Custom Automated Process Monitoring Systems

Powerful + Low Cost + Easy Install Monitoring Systems for Process Improvement

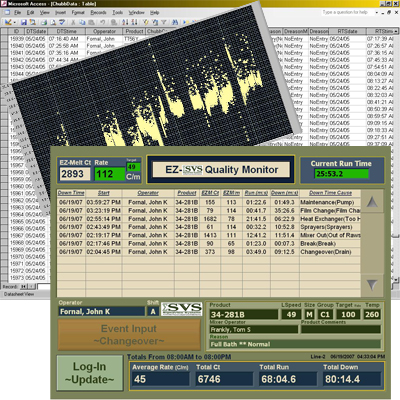

Powerful Automated Production Monitoring Data

SVS Automated Process Monitoring Systems provide invaluable Data Driven Quality Control and Production Streamlining. Direct Bottom Line Benefits are easily realized from Lower Defects and Increased Production Efficiency. Valuable Production Data is gathered for real time HMI Display Reporting and Database Archiving. Endless possibilities to what can be monitored and logged: Production Down Time Tracking, Down Time Cause, Down-Time segment duration pierods, Run-Time segment duration blocks, Production Output Piece Count, Production Speed, Production Rate, Operator Specific Production Outputs, Operator Caused Down-Time, Product Weight Tracking, Maintenance Events, Production Throughput, etc. All data is stored into a standard relational database structure capable of running SQL or MS-Access queries, exportation of data to Microsoft Excel, creation of Production Summary Reports, etc. With all data designed to be easily accessed, viewed, and evaluated for immediate production improvement results. Our Monitoring Systems generate incredibly powerful data that can be used to take your production to the next level of productivity and beyond..

Low Cost Turn-Key Fully Automated Monitoring Systems

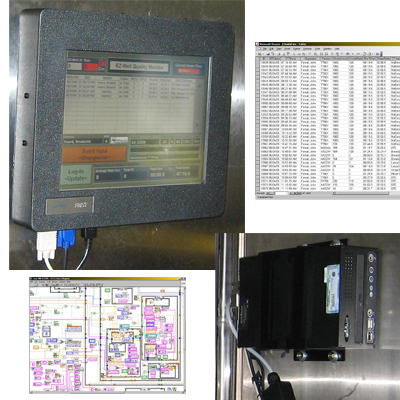

SVS Custom ‘Intelligent’ & Automated Process Monitoring Systems are designed to provide Powerful 'Smart' Logging Solutions, on a Low Cost & Easy to Install platform. Customized Base Monitoring System Kits, Complete and Ready to Install, start at $8999.99 (Compare to similar custom alternatives which run well over $25-$50K+ design, limited in features, and very complex to install or use). Our Process Monitoring Systems are Modular with standard base configuration applicable to most all automated industrial production type applications – allowing our system costs to be so low and still Fully Customizable. Complete SVS Monitoring Package Includes: (NEMA-4) 15” Industrial LCD Touch Screen Monitor (Sealed: Dust, Splash, Wash-Down rating), Industrial mini-PC DAQ processor (Windows XP Pro Based, network capable), all direct system cables, base interfacing, Customized Monitoring Software (LabVIEW Based), database software plus structure, standard mounting brackets, and remote support with single remote training session. Plus many custom mount, interfacing, and configuration options are available. Our Process Monitoring systems will include everything needed for an Easy ‘plug-n-play’ Installation.

Easy Automated Production Monitoring System Install & Setup

SVS Automated Process Monitoring Systems are designed to be extremely User Friendly and Easy to Install. Our Monitoring Systems are packaged into a Complete Kit and ready for an Easy Installation. Simply mount the mini Black Box 'Brain' / Processor PC (U-bracket included) inside an adjacent ventilated cabinet or protected dust free area (NEMA-4 PC Enclosure options available), then mount the NEMA-4 Touch Screen LCD Monitor with standard VESA Panel Mount (included), interface to target signal (any 24V trigger, pulse, cutter, valve, paddle, photo-eye, encoder, PLC, etc. -simply connect +/- cable to 24V control signal, serial communication, or Ethernet, etc., then plug in supplied cables, supply 120VAC, and system is ready to run.) Interfacing is custom configured depending on system / requirements, signal DAQ upgrade and process signal conditioning options available. Once Monitoring System is up and running, system is configured via settings within the admin functions section which is accessed directly via the touch screen, and or settings plus database can also be configured via direct file access. System / PC can also be placed onto local network (optional) for remote data access and database settings. Data and Settings can also be accessed directly through the touch screen front panel and data exported via thumb drive or similar. The SVS automated production monitoring system is completely self contained. Everything is designed to be as straightforward and easy as possible, from operator use to manager / supervisor configuration of system. User Friendly is a key design target of our Monitoring Systems. Many custom mount and configuration options are available. Remote support is also included for initial start-up and single remote training session..

Expertise in Automated Production Process Monitoring

SigmaView Systems (SVS) has a combined working experience of over 20+ years within the Electronics Engineering and Industrial Process Monitoring & Controls Field. Our Automated Production Monitoring Systems / designs are proven effective solutions, as we have many systems currently operating in multiple production facilities within the USA and Europe. Trust your Process Monitoring needs to the Experts and contact SVS today. A relatively small investment can go a long way in achieving new levels of Reduced Production Defects and Increased Production Efficiency..